Multi-metal pretreatment (chrome-free)

Passivation before painting

Application by dipping or spraying (chrome-free)

PRODUCT DESCRIPTION

BRUGAL® TREAT 050 is a passivating agent that improves adhesion and has been specially developed for paint pretreatment. It can be used in paint lines in both spray and dip processes.

BRUGAL® TREAT 050 reacts with the metal surface by passivating it, thus improving paint adhesion.

The product is particularly suitable for the treatment of steel and phosphated steel. However, it is also suitable for galvanized steel, zamak, aluminum and their alloys.

The preparation is designed for painting systems with liquid paints, paints in powder form and by cataphoresis. For more information, please contact the technical service.

TECHNICAL AND ECONOMICAL ADVANTAGES

APPLICATION FORMS

BRUGAL® TREAT 050 is applied by immersion or by spray gun in baths diluted with demineralized or distilled water. No rinsing is required after application, only drying, after which the pre-treated product is ready for painting.

The concentration recommended for the bath is 4–6% by volume, depending on the equipment and application system.

If you are interested and would like further information, please contact us specifically. You can also find out more at http://www.procoat-tech.com/de/. http://www.procoat-tech.com/de/ mehr hierzu erfahren.

Masking Solutions Standard & Special

Global Mask® specializes in the design of rubber parts for all types of industrial applications and uses.

Abre Technik’s product range thus consists of standard maskings as well as custom-made maskings. The standard maskings range from silicone plugs and caps to masking tapes & circular blanks as well as hoses & plates.

If the standard program does not meet your needs, we are able to offer custom made maskings. With these custom-built maskings, the development is tailored to fit your exact requirements. From the most simple custom tape molds to the most complex custom rubber masks. If you can picture it, it can also be produced!

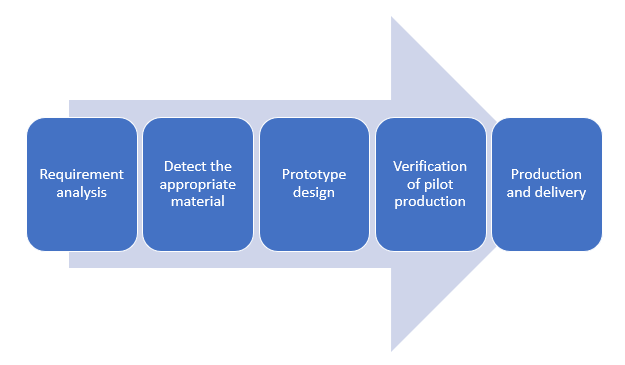

The standardized process for custom molds here is as follows:

No.1 We analyze your requirements

We find the standard part that best fits your requirements or design a part specifically for you.

No.2 We find the optimal material

We assist you in selecting the optimal material based on your functional and economic specifications.

No.3 Prototype design

The use of 3D technology ensures a lean development process.

No.4 Pre-series testing

Before the production and delivery of your parts, an initial sampling takes place

- You can check the correct fit of the parts in advance.

No.5 Delivery and production

We are service oriented and guarantee maximum flexibility in production

and delivery

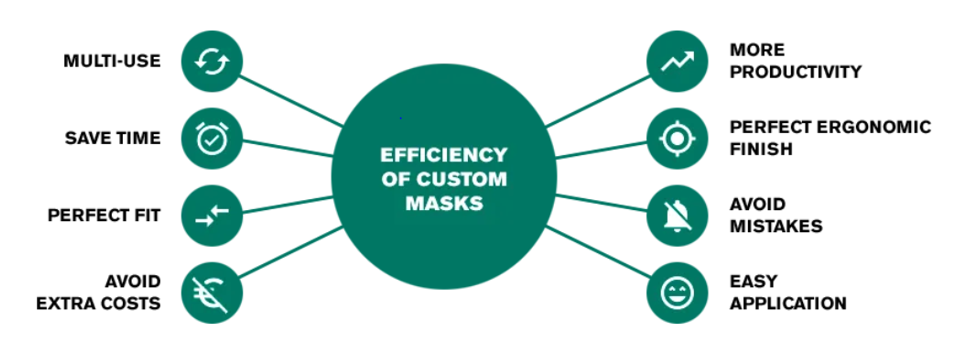

Your advantages for special parts

Custom masking products are designed specifically for your process and application requirements. The many benefits of custom masking contribute to higher and improved productivity.

Product overview

Bitte schauen Sie sich hierfür die hier angehängte Datei „Produktübersicht Global Mask“ an.

Application Areas

For an overview of the application areas, please refer to the attached file “Application Areas Global Mask”. „Anwendungsgebiete Global Mask“ an.

We offer primarily wet paint on polyurethane or epoxy basis for repair and touch-up.

About Selemix

State-of-the-art technology for every application — Selemix!

Whatever you need to protect from environmental influences, whatever you need to give a new shine, Selemix makes it possible. The SELEMIX system is suitable for all types of surface coating, both industrial and craft. It consists of 17 high-quality and concentrated mixing bases and a diverse selection of binders. These components are used to create a coating system that can be adapted to any requirements. Particular attention is paid here to economy and quality. The flexibility of the binder-mixer combination allows a large number of application possibilities with minimal stock and financial outlay.

Industrial applications

Due to their chemical nature, Selemix® products can be used for the protection and coating of metallic substrates. Typical applications include:

Availability

For all available standard RAL colors and also special colors possible. Please contact us directly for this.

We offer wet paint on polyurethane or epoxy basis mainly for repair and touch-up in commercial vehicle quality. Depending on your needs, the application is done with a touch-up pen or with a practical spray can.

State-of-the-art technology for every application — Selemix!

Whatever you need to protect from environmental influences, whatever you want to give a new shine, Selemix makes it possible. The SELEMIX system is suitable for all types of surface coating, both industrial and craft. It consists of 17 high-quality and concentrated mixing bases and a diverse selection of binders. These components are used to create a coating system that can be adapted to any requirements. Particular attention is paid to economy and quality.

Industrial applications

Due to their chemical nature, Selemix® products can be used for the protection and coating of metallic substrates. Typical applications include:

Availability

For all available standard RAL colors and also special colors possible. Please contact us directly for this.

Note

Wet paint for the applications listed here in quantities between 5–10 kg can also be obtained from us. For larger quantities, please contact us directly.

Heat resistant 2 K filler is a two-component filler based on styrene dissolved unsaturated polyester resins. The product is characterized by the following properties:

Industrial applications

E‑Coat Repair Spray SPR51132-ZL Black Acrylic Silk Gloss

SPR51132-ZL is a 1K solvent-based KTL repair spray with combined technology for KTL defects and damage to existing KTL coatings.

Product properties

Industrial application

We offer the MCL (methylene chloride) free paint stripper for paint removal as a spray. This paint stripper is ideally suited for removing a wide variety of coatings, paints and other unwanted residues.

Industrial applications

for the removal of

from all common substrates such as stone, wood or metal.

Availability

Clear Coat

Note

Test for suitability on an inconspicuous area before application.