According to DIN EN ISO 8044- 2020, corrosion is the reaction of a metallic material with its environment, which causes a measurable change in the active substance and can lead to impairment of the function of a metallic component or an entire system.

For functional corrosion protection, we not only offer our corrosion protection products, but also want to support with relevant know-how.

Read more about this in our Letter of recommendation corrosion protection.

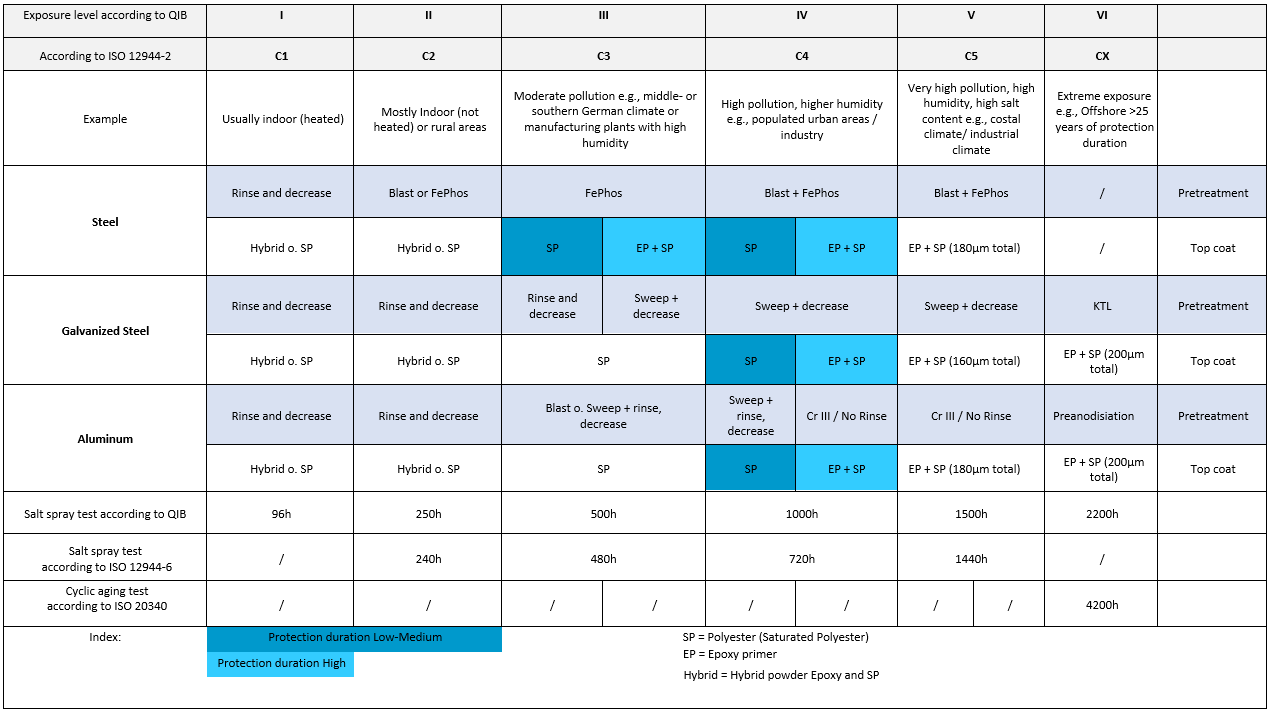

The decisive factor is the corrosivity category to be achieved as well as the duration of protection to be achieved

The following document is intended to provide an insight into typical pretreatment and coating options to achieve a required/suitable corrosion protection. This matrix is to be understood as a recommendation only and in no way provides a guarantee for achieving the desired protection category.

The quality and thus associated protection duration are strongly dependent on various factors such as

Regular process control is therefore essential to produce high quality and long life.

The following document is intended to provide an insight into typical pretreatment and coating options to achieve a required/suitable corrosion protection. This matrix is to be understood as a recommendation only and in no way provides a guarantee for achieving the desired protection category. (You can find the document here: Download)

The quality and thus associated protection duration are strongly dependent on various factors such as

Regular process control is therefore essential to produce high quality and long life.

It should also be noted that the corrosion protection classes are not applicable in the case of very severe corrosion loads, long protection periods and special loads. In the case of these loads and conditions, the necessary measures must be determined in each individual case. The protection period to be achieved by the coating system must already be known during planning and design. In general, the protection period is shorter than the expected service life.

Concluding remarks:

In the case of sharp-edged/lasered/punched components, burrs should always be removed and the edges rounded. In addition, the surface should be free of scale and oxidation layers!

High performance polymer blend coating powder

Plascoat® PPA 571 is specially formulated to provide a durable, robust coating on bare steel, galvanized steel, and aluminum for outdoor applications. It is based on an alloy of acid-modified polyolefins. It is halogen free and has low smoke and toxicity when burned.

Industrial applications

Plascoat® PPA 571 Series products are recommended for the protection and coating of metallic substrates for outdoor use where high corrosion resistance is required. Typical applications include:

Product Availability

| RAL 1000er | RAL 1015 | RAL 1021 | ||

| RAL 3000er | RAL 3009 | RAL 3020 | ||

| RAL 5000er | ca. RAL 5015 | ca RAL 5017 | ||

| RAL 6000er | RAL 6005 | |||

| RAL 7000er | RAL 7001 | RAL 7016 | RAL 7035 | ca. RAL 7046 |

| RAL 8000er | RAL 8019 | |||

| RAL 9000er | RAL 9005 | ca. RAL 9006 | RAL 9016 |

Product Features & Performance

Packaging units

Available in a variety of packaging, from mini-packs to 25kg cartons. Please contact us if you require additional pack sizes.

Advantages of Plascoat PPA 571

Plascoat® PPA 571 has many use cases, including fire extinguishers, battery troughs, fan shrouds, tanks, school furniture, shopping carts, stadium seating and submersibles. Regardless of the application, long-term field tests are available for Plascoat® PPA 571, substantiating the product’s outstanding properties

Multi-metal pretreatment (chrome-free)

Passivation before painting

Application by dipping or spraying (chrome-free)

PRODUCT DESCRIPTION

BRUGAL® TREAT 050 is a passivating agent that improves adhesion and has been specially developed for paint pretreatment. It can be used in paint lines in both spray and dip processes.

BRUGAL® TREAT 050 reacts with the metal surface by passivating it, thus improving paint adhesion.

The product is particularly suitable for the treatment of steel and phosphated steel. However, it is also suitable for galvanized steel, zamak, aluminum and their alloys.

The preparation is designed for painting systems with liquid paints, paints in powder form and by cataphoresis. For more information, please contact the technical service.

TECHNICAL AND ECONOMICAL ADVANTAGES

APPLICATION FORMS

BRUGAL® TREAT 050 is applied by immersion or by spray gun in baths diluted with demineralized or distilled water. No rinsing is required after application, only drying, after which the pre-treated product is ready for painting.

The concentration recommended for the bath is 4–6% by volume, depending on the equipment and application system.

If you are interested and would like further information, please contact us specifically. You can also find out more at http://www.procoat-tech.com/de/. http://www.procoat-tech.com/de/ mehr hierzu erfahren.

Epoxy series “P5”

PPG’s ENVIROCRON® complete and defined primer product portfolios designed for dedicated purposes including different chemistries for optimal anticorrosion protection of different substrates.

Product advantages

| Primeron | Primeron Zinc P512G000R-YD | Primeron Pro P511G508R-YD | Primeron Edge P513G091R-YD | |||

|---|---|---|---|---|---|---|

| Chemie |

|

|

| |||

| Merkmale |

|

|

| |||

| Vorteile |

|

|

| |||

| Corrosion Protection | Excellent Steel C4 High | Excellent With hot dip galvanizing: C5 | Excellent Steel C4 High | Excellent With hot dip galvanizing: C5 | Excellent Steel C4 High | Excellent With hot dip galvanizing: C5 |

Product Availability

| Gloss (60º gloss meter) | Low Cure Series | Medium Temperature | High Temperature |

|---|---|---|---|

| Low: < 30 GU (Gloss Units) | – | – | P513 Series |

| Medium: 30–70 GU (Gloss Units) | – | P522 Series | P512 Series |

| High: >70 GU (Gloss Units) | P531 Series | P521 Series | P511 Series |

| Structure | P53xT Series | P52xT Series | P51xT Series |

| Fine Texture | P53xF Series | P52xF Series | P51xF Series |

Not all surfaces and gloss levels are available on stock. Please contact us for further information.

For additional information on individual products, please refer to the respective technical data sheets.

Special properties

Color and metallic powders

Available in a variety of uniform and metallic colors. Also available as a clear coating.

Coatings and surface effects

Available in a wide range of gloss finishes and surface effects.

Packaging Unitserpackungseinheiten

Available in a wide range of packaging from mini-packs to 20kg cartons to 650kg containers.

Image source: https://www.ppgindustrialcoatings.com/de-DE/technologies/powder-coatings

For additional information on individual products, please refer to the respective technical data sheets.

Colore® P.4 is an epoxy-pur series based on pure epoxy resin. It is free of heavy metals and TGIC. The powder coating film after polymerization has very good mechanical properties and good flow characteristics. Furthermore, the series demonstrates excellent resistance to chemicals (detergents, propellants, lubricants…) and excellent corrosion protection.

Industrial applications

The epoxy primer white smooth matt, as well as all the other products in the composition of the series P.4 Colore®, can be used only for the protection and coating of metallic substrates for indoor use: Typical applications include:

| Surface | Gloss Level | Gloss Unit |

|---|---|---|

| Smooth | Matt | 5–10 GU (Gloss Units)* |

| Smooth | Metallic/Multicolor | |

| Fine Texture | Matt | |

| Fine Texture | Metallic/Multicolor |

Color and metallic powders:

For all available standard RAL colors and also special colors according to template. Minimum quantity for individual productions from 25 kg.

Verpackungseinheiten:

The product is packed in plastic bags in cartons of 20 or 25 kg.

Colore® P.35 thermosetting powder coating formulated with polyester resin and light-resisting pigments. After polymerization, the powder coating film has good resistance properties with respect to weather conditions and chemical agents (detergents, propellants, lubricants…). Due to its innovative chemical nature guarantees anticorrosive performances significantly superior to comparable polyester products.

Industrial applications

P.35 Colore® series products are recommended for the protection and coating of metallic substrates for outdoor use where high corrosion resistance is required. Typical applications include:

| Surface | Gloss Level | Gloss Unit |

|---|---|---|

| Smooth | Glossy | 71–95 GU (Gloss Units)* |

| Smooth | Semi Glossy | 51–70 GU (Gloss Units)* |

| Smooth | Metallic/Multicolor | |

| Fine Texture | Matt | |

| Fine Texture | Metallic/Multicolor | |

| Rough Texture | Glossy | |

| Rough Texture | Semi Glossy | |

| Rough Texture | Metallic/Multicolor |

Color and metallic powders

For all available standard RAL colors and also special colors according to template. Minimum quantity for individual productions from 25 kg.

Packaging units

The product is packed in plastic bags in cartons of 20 or 25 kg.